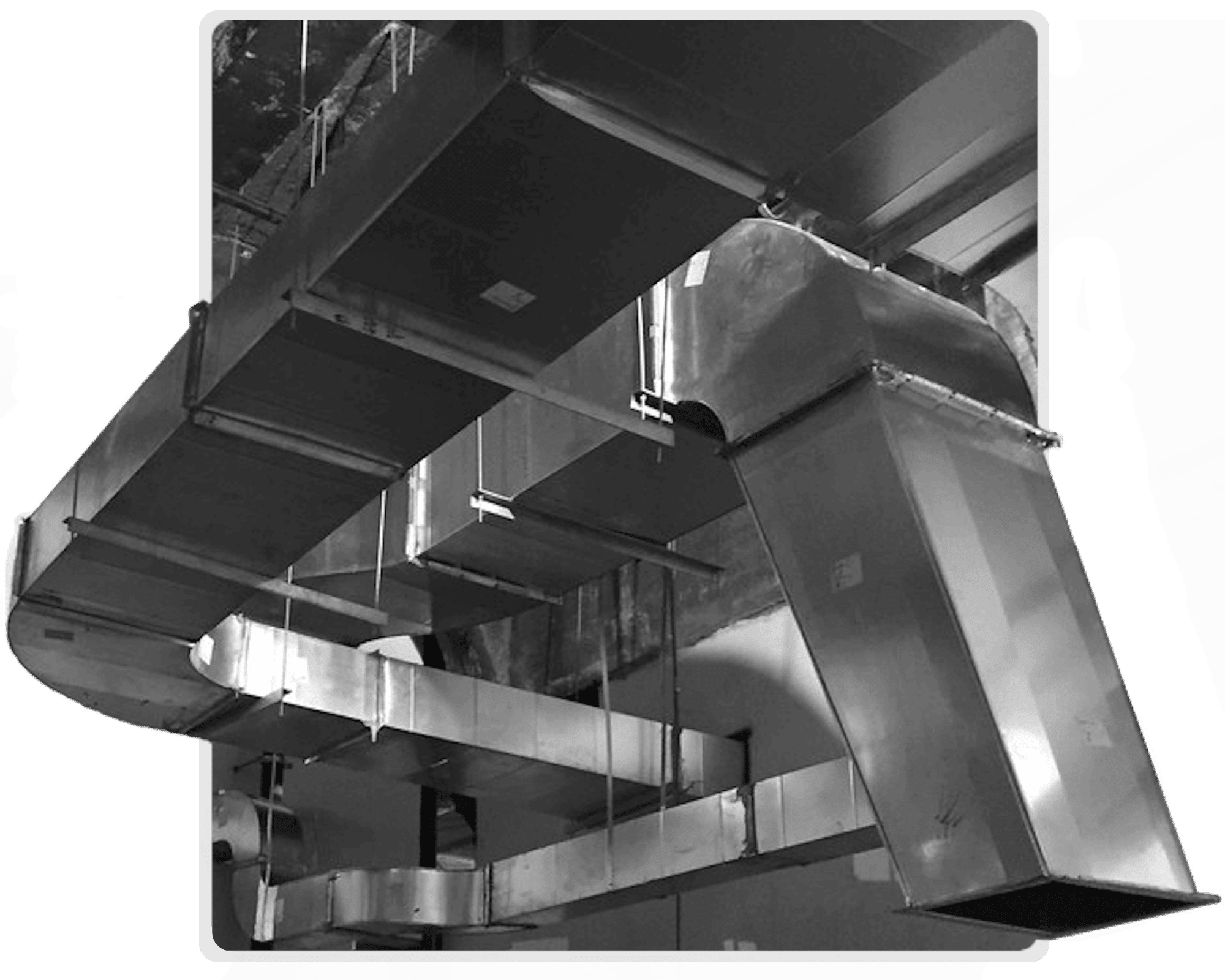

Duct Unlimited

Duct Unlimited was formed in 2021 resulting from what we saw as a need of HVAC/General Contractors for quality, made-to-specifications ductwork with quick turnaround times.

As owners of a full line sheet metal fabrication shop and an air conditioning company since 1964, we decided to get into the manufacturing side of the business.

From straight pieces of square duct to a large assortment of fittings, lined or unlined, we would love the opportunity to quote your project.

Capabilities

We currently have the following tools at our disposal:

Autofold 516

Used in making straight duct. Metal comes to us in coils, the rolls are put onto the Autofold. The Autofold unrolls the coils, cuts, notches, and bends the metal into pieces of straight duct. Also used to cut flat sheets to a specified length.

Engel Europa Flange Rollformer

Turns TDF flanges on the end of straight duct work and fittings for flanged connections. Cuts “clips” used in making flanged connections.

Fabri Flange 516

Hydraulic powered break. Used to break (bend) sheetmetal. Notches allow for flanged duct.

Flagler Powered Cleatbender - Drive Turning Machine

Turns drives on the ends of duct for S and Drive connections.

Iowa Precision Cornermatic

Inserts corners (one at a time or top and bottom simultaneously) into the corners of flanged duct.

Iowa Precission Whisper-Loc Pro-XVI

Used to quietly close Pittsburgh seams on duct work.

Plasma Cutting Machine

Able to cut duct fittings, parts, designs, etc. from sheet metal (cutting bed 5' x 10' and can cut up to ¼” in thickness).

Vicon V8 Pittsburgh-Slip & Drive Rollformer

Turns Pittsburgh seams and ¼”- ½” edge. Cuts drive slips, and S-locks for use in making S and Drive connections.

All of our duct fabrication is built to meet and exceed the Sheet Metal and Air Conditioning Contractors' National Association (SMACNA) standards.